Delivered by

Subtotal

* Tax & shipping calculated at checkout.

Get Extra 10% OFF Coupon Code: Happy10 COPIED

Delivery Options

Delivered by

(800) 735-4304

Talk to real personWe're offlineonline now

Our work schedule

Mon - Fri / 8am - 6pm

Saturday / 8am - 3pm

(You can call anytime during work time)

Delivery Options Choose at Chechout

Free Shipping

Arrives By

Rush Delivery

Arrives By

Need Sooner?

Call us! (800) 735-4304

*shipping options will be available during checkout.

Average response time: 5-7 mins

Get high-quality custom screen printing in Fort Worth with fast turnaround, durable results, and no minimums. Perfect for events, merch, teams, and more.

We offer custom screen printing in Fort Worth on a wide range of quality items. Everything is printed with precision, built to last, and delivered on time.

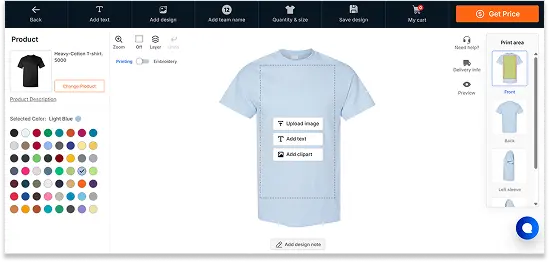

View All ProductsOrdering is simple. No runaround, no confusing forms. Here's how it works from start to finish:

Choose Your Product

Pick what you want to print on. T-shirts, hoodies, sweatshirts, polos-whatever fits your need. If you're not sure, we’ll help you find the right option.

Send Your Design

Upload your artwork, logo, or text. We accept all common formats. If your file needs cleanup or resizing, we’ll handle it before print.

Select Quantity and Sizes

Let us know how many pieces you need and in which sizes. There’s no minimum, and pricing is based on item, quantity, and design.

Print and Delivery

Your order is screen printed right here in Fort Worth. You can pick it up, get it delivered locally, or have it shipped anywhere you need.

Take a look at recent custom screen printing jobs we've completed in Fort Worth. All designs are printed locally with consistent quality and fast turnaround.

Design Custom T-shirts and Apparel for Your Company, Team or Event

Every design, garment, and order size requires the right method, not a default one. At our Fort Worth shop, we use multiple types of screen printing to ensure your prints come out clean, consistent, and durable. Below is a full breakdown of each method, including how it works, what it’s best for, and when we use it.

Plastisol is the foundation of most screen print shops, and for good reason. It delivers solid, opaque prints that hold up to repeated wear and washing, without soaking into the fabric.

Water-based printing is chosen for comfort, not just looks. Instead of coating the fabric, water-based ink absorbs into the fibers, creating a lightweight, print-free feel.

Discharge printing chemically removes the dye from dark garments and replaces it with pigment. The result is a bright, soft print with no ink buildup.

Puff ink creates a 3D, raised texture that expands during curing. It gives your print a physical presence and is often used for detailed emphasis.

When you need something different-inks that shimmer, reflect, or glow-our specialty screen printing methods are built for visual impact.

We don’t expect you to know which method fits your job best-that’s our role. When you place an order, we look at the file, fabric, order size, turnaround time, and the kind of result you’re aiming for. From there, we pick the right screen printing method and set it up in-house at our Fort Worth shop. Every job is reviewed by a production lead before we run anything through the press.

We print the things people actually wear and use, not just what looks good in a catalog. Every product here has been tested on real presses, in real runs, with real clients. If it didn’t work, it’s not on this list. If it’s here, it prints clean, fits right, and survives the wash.

We don’t pick products based on trend. We pick what prints clean, fits right, and holds up after wear. Everything listed here runs through our shop because it works-not just once, but over and over. If you're ordering from us in Fort Worth, you're getting gear we trust enough to print every day.

Most orders are ready in 3 to 5 days. If you need it sooner, we can rush it depending on press time and stock.

Yes, we require a minimum of 3 pieces per design. This covers the setup time, screen prep, and press alignment needed for proper screen printing.

Most orders land between $8 and $15 per shirt. Bigger orders cost less per piece.

Yes. Our quotes include screens, setup, and print-no surprise add-ons.

Yes. As long as the design and ink colors stay the same, you can mix sizes without extra setup.