Delivered by

Subtotal

* Tax & shipping calculated at checkout.

Get Extra 10% OFF Coupon Code: Happy10 COPIED

Delivery Options

Delivered by

(800) 735-4304

Talk to real personWe're offlineonline now

Our work schedule

Mon - Fri / 8am - 6pm

Saturday / 8am - 3pm

(You can call anytime during work time)

Delivery Options Choose at Chechout

Free Shipping

Arrives By

Rush Delivery

Arrives By

Need Sooner?

Call us! (800) 735-4304

*shipping options will be available during checkout.

Average response time: 5-7 mins

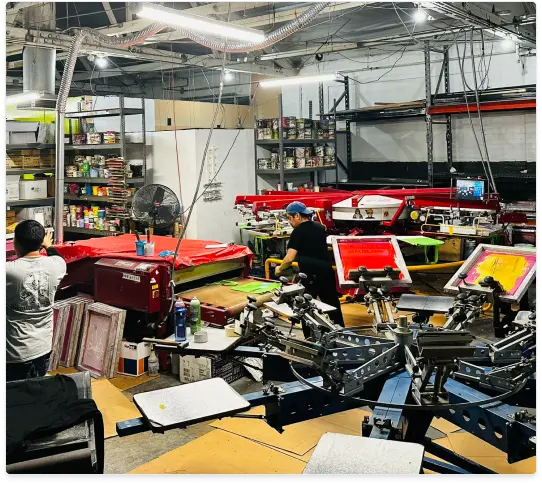

Get high-quality custom screen printing with fast turnaround, great prices, and reliable results for t-shirts, hoodies, and more.

100,000+ Customers & Leading Companies Trust Our Custom Screen Printing Services!

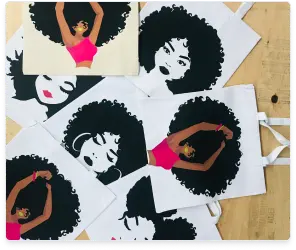

Design t-shirts, hoodies, and more with custom screen printing for your company, team, or event.

View All ProductsTake a look at our custom screen printing work, featuring high-quality prints on t-shirts, hoodies, and more.

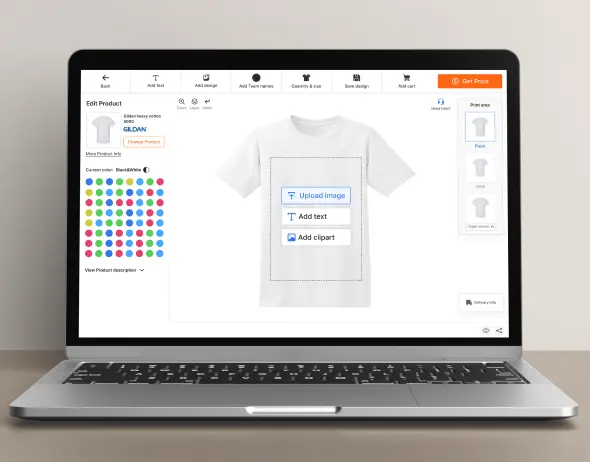

Choose Your Product

Browse our selection of t-shirts, hoodies, and other apparel. Pick your preferred style, color, and material.

Upload Your Design

Upload your artwork, logo, or text to customize your product exactly how you want it.

Check Out

Review your order details and proceed with payment.

Durability:

One of the primary benefits of custom screen printing is its durability. The thick layers of ink used in this method create vibrant, long-lasting prints ideal choice for custom t-shirts, custom hoodies, custom tote bags, and other apparel.

Cost-Effectiveness for Large Orders:

Custom screen printing becomes increasingly cost-effective as the order size grows. The setup costs are distributed over a larger number of items, reducing the cost per unit.

Versatility:

Custom screen printing is highly versatile and can be used on a wide range of products, including custom sweatshirts, custom polo shirts, hoodies, sweatpants, shorts, and bags.

High-Quality Results:

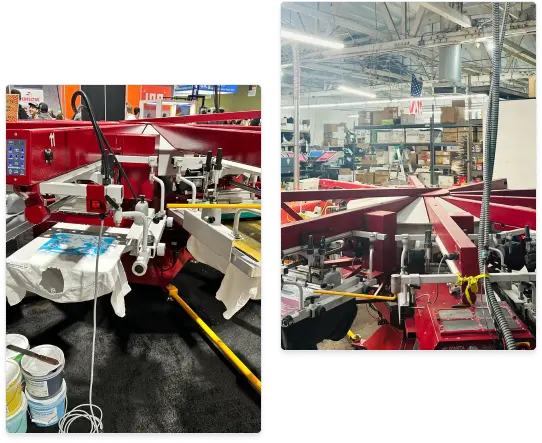

Our custom screen printing services deliver high-quality, vibrant prints that are both durable and visually appealing. We use premium inks and state-of-the-art equipment to ensure your designs look their best.

Low Minimum Orders:

We understand that not every project requires a large quantity of items. That’s why our custom screen printing shop offers the lowest minimum order requirements in the entire industry, providing flexibility for businesses, and individuals.

Fast Turnaround:

At Rapid Printing & Embroidery, we pride ourselves on our fast turnaround times. Whether you need a rush order for an upcoming event or simply want your items delivered quickly, we’ve got you covered.

Design Preparation

The process starts with an idea that turns into a design, logo, or text. For the best results, submit designs in a vector file, scaled to the print size. Recommended formats include PSD, EPS, PNG, and JPG.

We separate your design by colors, and each color is printed onto a transparent film. These films are essential for creating the screens used in the printing process.

The transparent film is taped onto a coated screen to prevent movement. The screen is then placed in the exposure unit for 2 to 10 minutes, depending on the unit.

After exposure, the screen is washed indoors with a power washer, away from UV light, to remove the soft emulsion. This leaves the design area open for ink. The screen is then dried in a darkroom drying rack.

Registration ensures that the screen image aligns with the original artwork, making sure each color in the separation lines up correctly relative to the others.

Proper ink preparation is crucial for achieving high-quality results. We recommend using plastisol ink due to its ease of use and superior print quality compared to water-based inks.

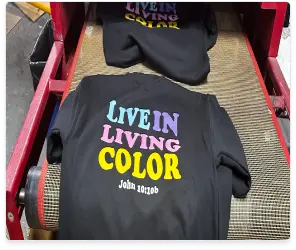

Once the shirts are printed, they are placed on the belt of a conveyor dryer to cure the ink, ensuring the durability and longevity of the print.

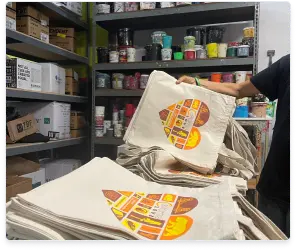

After drying, the t-shirts are ready for packaging. They are carefully placed in boxes and prepared for shipping to customers or local pickup.

Custom screen printing is one of the most popular methods for printing designs on fabric, particularly for apparel such as t-shirts, hoodies, and promotional merchandise. It involves pressing ink through a mesh screen onto fabric using a stencil, ensuring high-quality and long-lasting prints. The process is ideal for bulk production and is widely used in branding, team apparel, and event merchandising.

When choosing between custom screen printing and DTG printing, it’s important to understand how each method performs in real-world applications. While both have their place, screen printing remains the industry standard for businesses and brands that need reliable, high-quality prints at scale. DTG is useful in certain situations, but when long-term quality and efficiency matter, screen printing offers clear advantages.

Custom screen printing applies ink in layers, creating a print that holds its color and shape over time. The process allows for precise color matching, which is especially important for branding. The ink sits on the fabric, making colors more defined and resistant to fading. This method is widely used for retail clothing, corporate branding, and promotional products because it provides consistent results across large production runs.

DTG prints directly onto the fabric using water-based inks, which makes it capable of producing complex, multi-color designs with fine details. However, because the ink soaks into the fibers rather than sitting on the surface, colors can appear slightly muted, especially on dark fabrics. DTG prints tend to have a softer feel, but the colors may lose intensity after repeated washing.

One of the biggest advantages of custom screen printing is durability. The inks used in screen printing are thicker and bonded to the fabric through heat curing, allowing them to withstand repeated washing without significant fading or cracking. This makes screen printing a great choice for work uniforms, sports apparel, and branded merchandise that needs to maintain its quality over time.

DTG uses water-based ink, which absorbs into the fabric rather than sitting on top. While this creates a softer print, it also means that after 30-50 washes, the design may start to fade-especially on darker fabrics. The lifespan of a DTG print depends on washing and drying methods, but generally, it is not as long-lasting as screen printing.

Screen printing is not limited to just cotton-it works on polyester, blends, moisture-wicking fabrics, nylon, and even specialty materials like canvas and leather. This makes it the preferred method for companies producing a variety of branded products, sportswear, or promotional items.

DTG requires a high cotton content to absorb the ink properly. 100% cotton shirts work best, while polyester and blended fabrics may cause the design to appear faded or less vibrant. This limitation makes DTG less practical for printing on athletic apparel, corporate uniforms, or specialty items.

Once the screens are prepared, the printing process itself is extremely fast and efficient. Hundreds of shirts can be printed per hour, making it the preferred method for large orders. The consistency across all prints ensures uniform branding and a professional finish.

DTG prints one item at a time, and each print can take several minutes. This makes DTG ideal for one-off custom shirts but impractical for large orders where speed and efficiency are necessary.

Custom screen printing is the best option for businesses and brands that need high-quality prints that last. It works on a wide range of fabrics, handles large orders efficiently, and ensures the design stays vibrant over time. That’s why it’s commonly used for retail clothing, uniforms, event merchandise, and promotional products.

DTG is useful for small custom orders and highly detailed designs, but when you need prints that hold up over time, work on different materials, and can be produced quickly in bulk, custom screen printing is the smarter choice.

For businesses and organizations that need large quantities of custom apparel, bulk screen printing is the most efficient way to produce high-quality, long-lasting prints at scale. Whether you're supplying branded merchandise, uniforms, or event apparel, large orders offer better pricing, faster production, and consistent quality across all items.

Custom screen printing is built for efficiency. Once the screens are prepared, prints can be produced rapidly, maintaining sharp details and vibrant colors on every garment. This makes it the preferred method for businesses that need hundreds or thousands of items printed with the same design. Unlike smaller production methods, bulk screen printing ensures:

Larger orders qualify for wholesale pricing, where the cost per item decreases as the order size increases. Pricing is influenced by:

Businesses with recurring needs often benefit from contract screen printing, which ensures consistent pricing and scheduled production for ongoing orders.

Managing a bulk order requires precision, and quality control at every stage ensures a consistent final product. From ink mixing to curing, each step is optimized for durability, color accuracy, and a clean finish on every garment.

If you’re looking for a trusted screen printing partner for large orders, we offer competitive pricing, reliable turnaround times, and guaranteed quality. Contact us today to discuss your printing needs.

Choosing the right ink is a key part of getting the best results in custom screen printing. The type of ink affects how the design looks, how it feels on the fabric, and how well it holds up over time. We use different inks depending on the fabric, the style of print, and the overall purpose of the apparel.

Plastisol is the most widely used ink in custom screen printing because it works on almost any fabric and produces sharp, durable prints. It sits on top of the material rather than soaking in, which makes the colors stay bright and crisp even after many washes.

This is the go-to ink for most custom screen printing jobs because it delivers reliable, long-lasting results across different fabrics and designs.

Water-based ink works differently from plastisol because it soaks into the fabric rather than sitting on top. This creates a lighter, softer print that feels like part of the material instead of an added layer.

Water-based ink is a great choice for brands that want a more natural look and feel or for customers who prefer an eco-friendly printing option.

Discharge ink is a special type of water-based ink that removes the dye from the fabric, replacing it with a new color. Instead of adding a thick layer of ink, it creates a print that blends into the fabric.

If you’re looking for a print that is completely soft to the touch, discharge ink is one of the best options, but it works only on certain types of cotton fabric.

For prints that need something extra, we offer specialty inks that create different effects.

These inks are used for custom branding, special promotions, and unique merchandise where a standard print isn’t enough.

The best ink depends on how you want the print to look and feel, how long it needs to last, and what fabric it’s being printed on.

If you’re not sure which ink is right for your project, we can help. Get in touch, and we’ll recommend the best option based on your design and fabric choice.

Color selection in custom screen printing is more than just picking shades that look good on a screen. The way ink behaves on fabric, the need for an underbase, and how colors interact with each other all play a role in the final result. A poorly chosen color combination can lead to dull prints, readability issues, or unexpected shifts in appearance once printed.

The same ink color can look different depending on the fabric it’s printed on. Light-colored fabrics allow most ink shades to appear as expected, but dark fabrics absorb more light, which can make colors look less vibrant.

For example, printing yellow ink on a black shirt without an underbase will result in a muddy, dull appearance because the fabric color overpowers the ink. In contrast, the same yellow on a white shirt will be bright and clear.

When printing on dark fabrics, a layer of white ink-called an underbase-is often used before applying the final colors. This prevents the fabric color from affecting the ink and helps maintain vibrancy. Without it, light-colored inks can appear faded, and even bold colors may not look as expected.

While an underbase helps with vibrancy, it also adds an extra layer of ink, which can slightly change the texture of the print. This is why some designs on dark shirts feel thicker than those on light fabrics.

Not all inks provide full coverage on every fabric. Some ink colors are naturally more opaque, meaning they sit on top of the fabric and block out the background color. Others are more transparent and allow some of the fabric’s color to show through.

For example:

Using the right ink type for the chosen fabric ensures the design appears exactly as intended.

Some color combinations may look good in a design file but don’t translate well to print. Low-contrast color choices-such as dark red ink on a black shirt-can make the design difficult to see, especially in certain lighting conditions.

When choosing colors:

Many people design their prints using RGB or CMYK color modes, but custom screen printing uses Pantone color matching for accuracy. A shade that looks one way on a digital screen may appear different when mixed with ink.

To get consistent results:

A well-thought-out color strategy can make the difference between an eye-catching, professional print and a design that looks washed out or dull. Taking fabric color, ink opacity, contrast, and underbase printing into account ensures that prints come out looking exactly as intended. If you're unsure about the best color choices for your order, reach out to us-we'll guide you to the best solution for the highest quality results.

A well-known summer music festival, attracting over 50,000 attendees annually, had a recurring issue-event merchandise that didn’t generate excitement or sell out.

Despite offering t-shirts and hoodies every year, sales were sluggish. Leftover stock had to be heavily discounted on the last day, cutting into profits. Attendees didn’t see the merch as anything special-just another event souvenir rather than a must-have item.

On top of that, festival-goers had complaints about quality. Many reported that previous shirts shrank after the first wash or that prints cracked and faded quickly. The festival team realized that without a better approach, they were missing a major opportunity to turn merchandise into both a revenue stream and a branding tool.

The organizers knew that just offering shirts wasn’t enough-they needed to make them something people actually wanted. The goal was to:

To transform their festival merch, we recommended premium screen printing on high-quality apparel from Comfort Colors and AS Colour, ensuring the products were built to last.

Instead of standard cotton t-shirts, we used:

For hoodies, we used:

This shift from basic promo apparel to high-quality, retail-standard products helped justify higher pricing and positioned the merch as a fashion item, not just a souvenir.

In previous years, festival shirts suffered from fading and cracking, leading to negative feedback. We resolved this by using:

This guaranteed that festival-goers wouldn’t deal with cracked prints after a few washes, making the merch feel like a true retail product.

By upgrading the quality, introducing exclusive designs, and creating urgency, the festival turned its merchandise from an afterthought into a core part of the attendee experience. Now, their annual merch drops are just as anticipated as the festival lineup itself.

An online influencer with over 500,000 followers across Instagram and TikTok decided to launch their first-ever merchandise line-something their audience had been requesting for months. The goal was simple: create high-quality, streetwear-inspired t-shirts and hoodies with a minimalist logo and a custom phrase that resonated with their brand.

Excited to get things moving, they partnered with a low-cost online screen printing service that promised fast turnaround and bulk pricing. The influencer placed a 1,000-piece order, expecting premium-quality shirts that their audience would love.

But when the shipment arrived, things went wrong fast.

With hundreds of unsatisfied buyers and a potential hit to their brand reputation, the influencer had to act fast to fix the situation.

This wasn’t just a failed merch drop-it was a direct hit to their personal brand. Fans had trusted them to deliver a quality product, and now many were asking for refunds or voicing their disappointment in the comments.

The influencer had to decide:

If they didn’t get it right this time, they risked losing credibility and damaging their brand permanently.

After researching custom printing companies, the influencer reached out to us to completely revamp their merch line with high-quality screen printing and premium apparel. Here’s how we helped them fix their merch drop and restore their reputation:

Instead of using cheap, mass-produced blanks, we recommended:

This alone made a huge difference-fans would immediately feel the quality as soon as they put the shirts on.

To avoid cracking and fading, we switched to:

We handled the entire production process, from bulk printing to quality control and shipping. Instead of rushing, we focused on getting everything right the first time, so the influencer could confidently relaunch their merch without worrying about quality issues.

Cutting corners on printing might seem like a way to save money, but in reality, it costs more in refunds, lost trust, and wasted inventory. By choosing high-quality materials and professional screen printing, this influencer not only rescued their merch line but also set themselves up for long-term success.

If you’re launching custom apparel and want to get it right the first time, reach out to us. We’ll help you create high-quality merch that represents your brand the way it should.

Yes, custom screen printing is highly durable. The thick layers of ink create vibrant prints that can withstand multiple washes without fading or cracking, making it ideal for long-lasting apparel.

Yes, our minimum order for custom screen printing starts at just 3 pieces.

We offer fast turnaround times, including rush orders for urgent needs. Depending on the size and complexity of your order, we can deliver same day to a week.

We recommend submitting your design in vector formats such as PSD, EPS, PNG, or JPG. These formats ensure the highest quality prints.

We can print up to 6 solid colors. For designs that require more than 6 colors, we offer halftone screen printing, which can create the appearance of additional colors by varying the density of dots.